Corrosion Control

The pot bearing fabrications are mainly steel plates, the corrosion protection influences the life-cycle of bearing greatly. Good corrosion protection reduces a lot of maintenance cost and extends bearings's life-cycle.

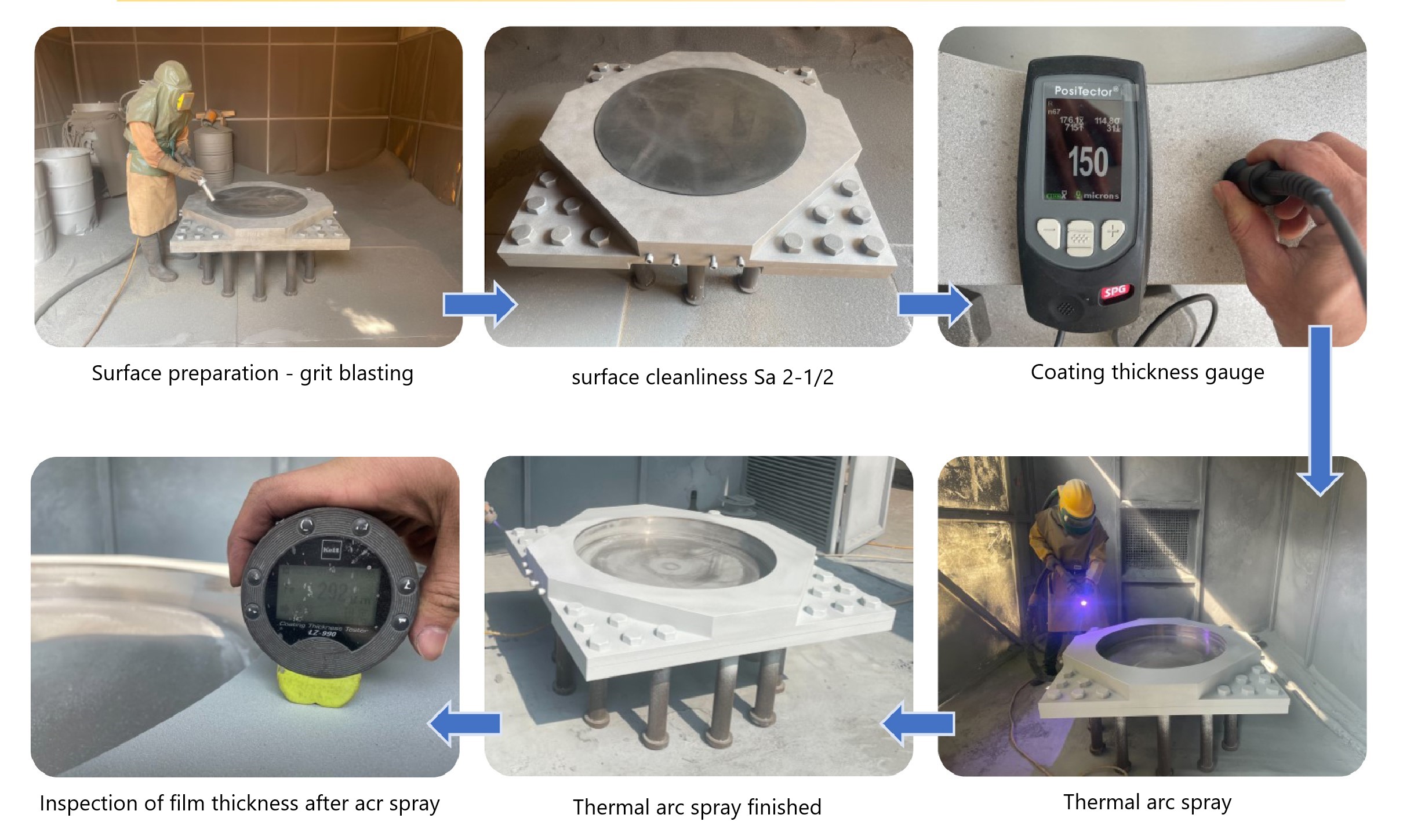

For the best quality, we have applied the metal arc spray for all Pillar pot bearings.

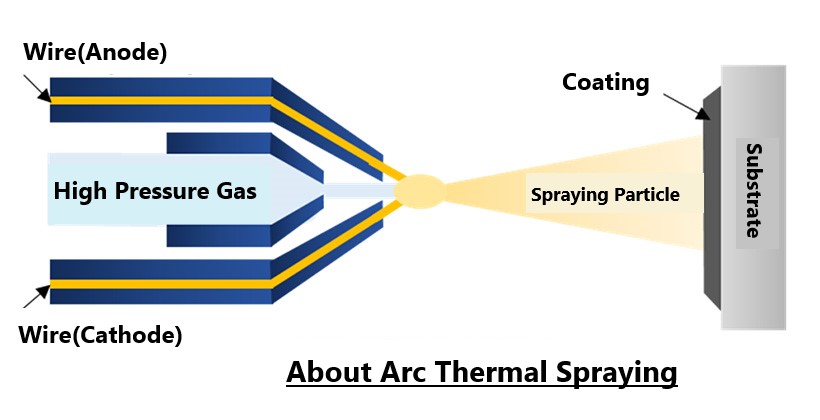

Zinc Arc Spray is the standard corrosion protection for Pillar pot bearings. Arc sprayis a process that uses an electric arc to melt wires. Not only the zinc wire, we can also use other wires (i.g., Al-Mg) as per the customer's requirements.

The performance of thermal arc spray on our pot bearings used in Taiwan High Speed Rail has been proved excellent. After 20 and more years since the installaion, our pot bearings have not founded any problems of corrosion in Taiwan High Speed Rail. PILLAR Taiwan Co., Ltd. also supplied many pot bearings in some Expressways in Vietnam with applying the Al95%-Mg5% thermal arc spay. We also passed the 6000 hours salt spray test conducted at Vietnamese laboratory.

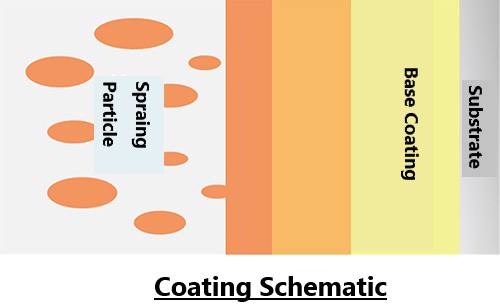

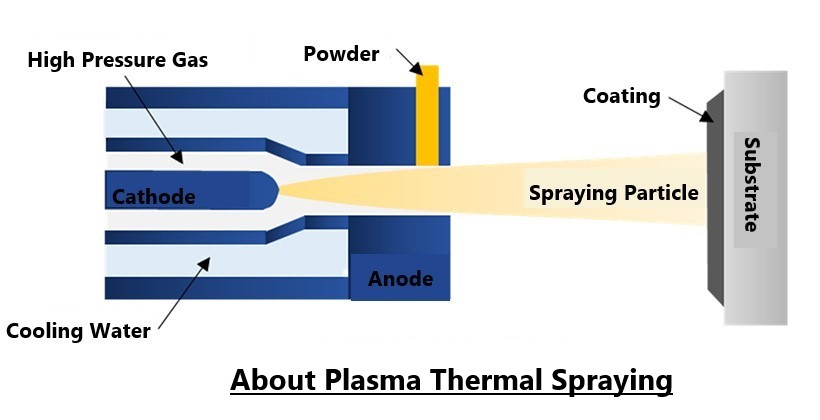

- The thermal arc spray is a process incorporation an electric arc as heat source for melting arc material. By an air stream the molten metallic particles were propelled onto the substrate to be coated.

- The source of heat of arc spray can be divided into two types: electric type and gas type. The electric type can be divided into two technologies: Plasma Spray and Arc Spray.

- To enhance the adhesion of metallic particles the surface of steel plate must be clean and has proper roughness therefore the process of grit blasting is required prior to arc spray.

- The applied top coating after arc spray not only repairs the surface but also enhances the hardness and abrasive resistance as a result to extend the service life.

- Spacing saving

- Achieve the reqired film thickness by one time application

- No drying time

- Expectable life time

- Widely application, suitable for irregular shapes of the substrates

- Excellent performance of cossosion protectoin and resistacne to abrasive

- Low heating of the substrate makes no torsion and no influence to the steel plate

- Topcoat can be applied after arc spary